In today's dynamic world of logistics, efficient warehouse management is the key to success. Every minute and every square meter is of paramount importance, and losses due to inefficient processes can generate huge costs. That's why more and more companies are choosing to implement modern technologies such as real-time location systems (RTLS). RTLS is a solution that makes it possible to accurately locate 0resources, optimize routing and improve security in the warehouse. In this article, you'll learn how RTLS works, the benefits of implementing it and the reports that will help you realize the full potential of this technology.

How RTLS works – real-time localization

RTLS (Real-Time Location System) is a system that allows tracking the location of objects in real time. It works by using transmitters (tags) placed on localized objects (e.g. forklifts, pallets, tools) and receivers (anchors) placed within the monitored area. The tags emit radio signals, which are received by the anchors. Based on the signal's arrival time or strength, the system calculates the location of the tags with an accuracy of several tens of centimeters.

There are several technologies used in RTLS systems, including:

- UWB (Ultra-Wideband): offers high accuracy and noise immunity, ideal for precision monitoring in complex environments.

- Bluetooth: cheaper and more energy-efficient alternative, suitable for smaller-scale tracking.

- RFID (radio-frequency identification): a technology based on radio-frequency identification that allows objects to be located using radio waves.

The choice of appropriate technology depends on individual needs and characteristics of the warehouse.

Application of RTLS technology in the warehouse

Optimization of warehouse forklift routes

One of the key applications of RTLS in the warehouse is the optimization of forklift routes. The system monitors the position of forklifts in real time, analyzes the routes traveled and identifies areas where unnecessary trips or delays occur. This makes it possible to make changes in the organization of work, optimize the layout of the warehouse and reduce the time needed to complete tasks. This translates into savings in time, energy (including battery charging time) and reduced equipment wear.

Resource monitoring

RTLS allows you to precisely track the location of all assets in your warehouse, from raw materials and supplies to finished goods. This makes it easy to locate wanted goods, streamline the inventory process and prevent losses due to theft or warehouse management errors.

Improving security

RTLS also improves safety in the warehouse. The system makes it possible to designate hazardous zones (e.g. near machines or ramps) and monitor the movement of workers and forklifts. In the event of entering a dangerous zone or violating safety rules, the system generates an alert, informing the appropriate people of the potential danger.

Location of people

The RTLS system can also be used to locate employees in the warehouse. This facilitates communication, coordination of activities and allows you to quickly locate a person at any given time, affecting warehouse productivity.

RTLS on the warehouse floor - types of reports to help in logistics

RTLS systems offer a wide range of reports that provide valuable information about logistics processes in the warehouse. Here are some of them:

Live map – real-time location

Live map is a basic report in RTLS, which allows you to view the current position of all located objects (trucks, pallets, people) on the warehouse map. This allows you to monitor warehouse traffic in real time and respond to any problems or delays.

Zone creator – designate zones and danger areas easily

The Zone Creator allows you to easily define multi-purpose zones (e.g., reception zones, release zones, buffer zones, danger zones) and configure alerts related to traffic in these zones.

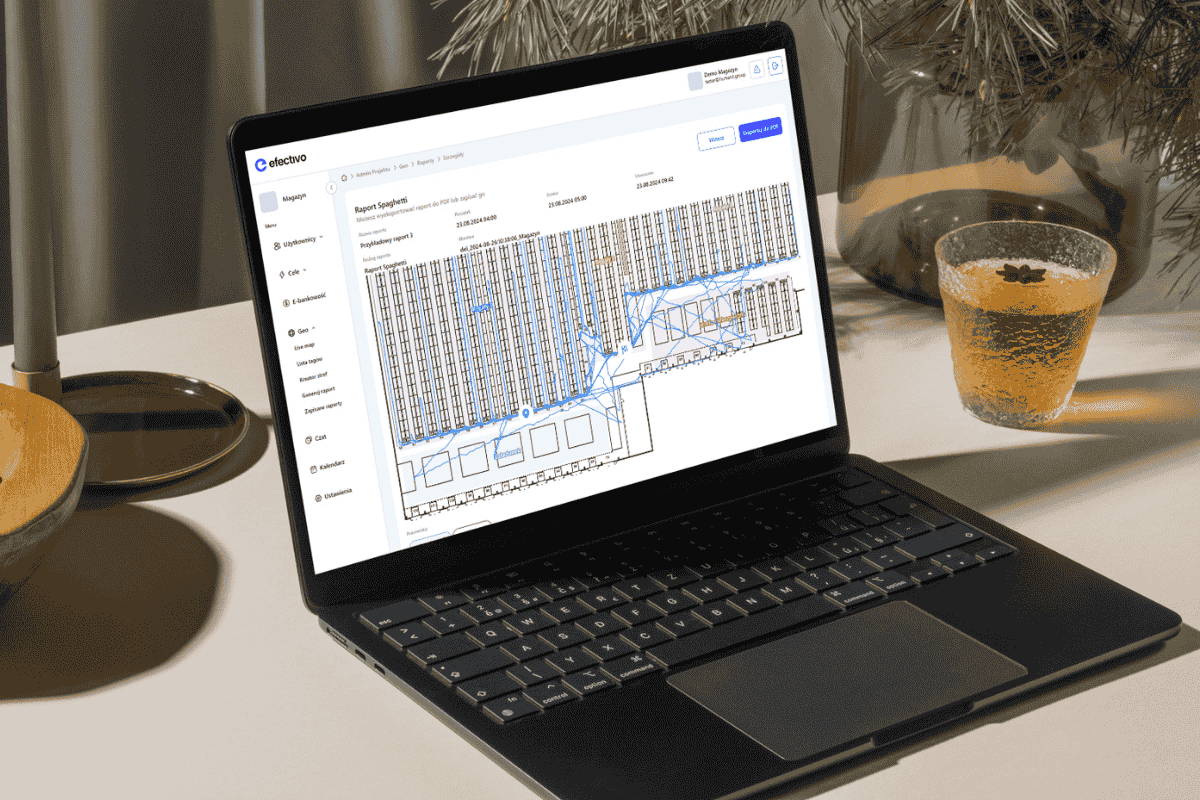

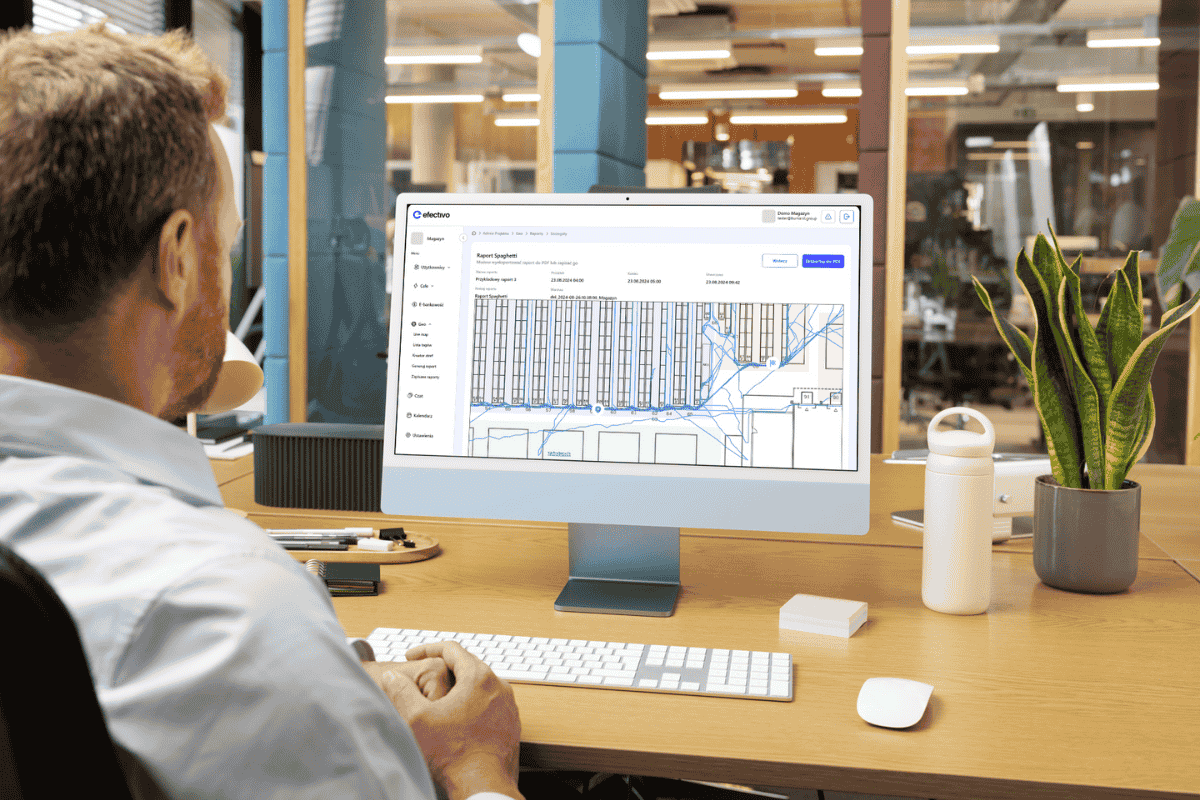

Spaghetti chart – reduce unnecessary activities

A spaghetti chart is a graphical representation of forklift travel routes. Analyzing the chart allows you to identify areas where unnecessary trips or crossing routes occur, allowing you to optimize your processes and reduce travel times.

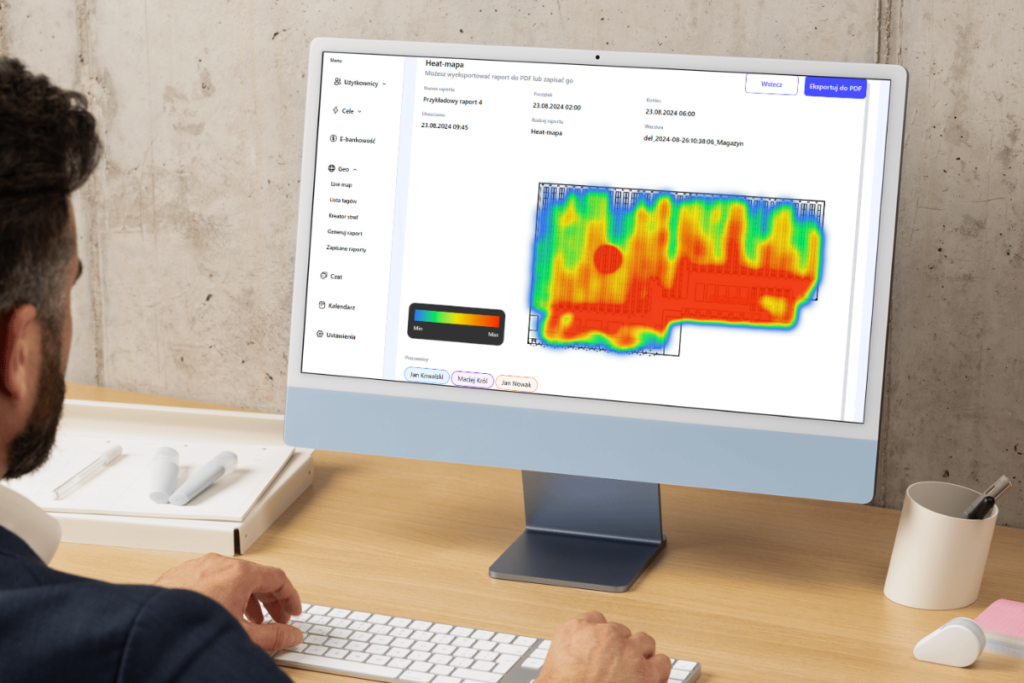

Heat map – increase the capacity of paths on the warehouse

Heat map is a graphical representation of traffic volume in the warehouse. High-traffic areas are marked with warm colors (e.g. red, orange), and low-traffic areas are marked with cold colors (e.g. blue, green). Analysis of the heat map allows identification of bottlenecks and optimization of the warehouse layout.

Zone load

The zone load report shows how warehouse space is being used. This allows you to optimize the placement of goods and ensure efficient use of available production space.

Hour by hour (HBH)

The hour by hour report shows labor productivity at different hours. Analyzing this report allows you to optimize your work schedule and make better use of human resources.

Resource distance

The resource distance report shows what distance a resource has traveled in a certain amount of time. This allows you to analyze route efficiency and identify potential areas for optimization.

Resource speed

The asset speed report shows the speed at which the asset is moving. This allows you to control the speed of forklifts and improve safety in the warehouse.

Traveled Distance Report

The distance traveled report shows the total distance traveled by an object in a certain period of time. This allows you to analyze the efficiency of your work and identify unnecessary trips.

The Danger Zone Report allows you to accurately monitor which workers and vehicles enter designated risk areas and how long they stay there. This allows you to:

The danger zone occupancy report shows how often and for how long a facility has been in hazardous areas. This allows safety monitoring and identification of potential hazards.

Real-time location in the warehouse – benefits

Implementing RTLS (real time location system) in a warehouse brings many benefits, among them:

- Save time and money: optimize routes in the warehouse, reduce turnaround time, reduce energy and equipment consumption.

- Improving safety: identifying hazardous areas, monitoring the movement of workers and forklifts, preventing accidents.

- Increase efficiency: streamlining logistics processes, improving use of warehouse space, better coordination of activities.

- Loss Reduction: preventing losses due to theft or errors in warehouse management.

- Improved customer service: faster order processing, greater availability of goods.

Use case: reducing operating costs by implementing RTLS in a warehouse

Company X is a large grocery distributor with an extensive network of warehouses. Prior to implementing the RTLS localization system, the company was experiencing problems with inefficient management of its fleet of forklifts (20 units). The trucks often traveled unnecessary distances, resulting in increased energy consumption and reduced productivity.

After implementing the efectivo GEO system, the company achieved significant benefits:

- Reduction of operating costs: thanks to the optimization of travel routes, the operating cost was PLN 2 per kilometer, which translated into daily savings of PLN 600 across the fleet; on an annual basis, the company saved PLN 150,000.

- Increase in the number of operations: per cart increased by 10% from 40 to 44 operations per day. Each additional four operations per day generated £40 in revenue per cart, which on an annual basis with 20 carts resulted in an additional revenue of £200,000.

- Improved safety: thanks to real-time alerts and the designation of hazardous zones, the frequency of worker and forklift traffic in hazardous areas was reduced. Each entry into a hazardous zone alerted the shift manager through the system.

Smart localization that optimizes processes

RTLS is an intelligent technology that allows companies to optimize logistics processes in the warehouse. With precise, real-time localization, you can reduce turnaround times, reduce operating costs and improve security. Implementing RTLS is an investment that pays for itself and brings tangible benefits to the company.

Want to learn more about how RTLS can help optimize your warehouse? Make an appointment for an online demo.