Lean Manufacturing is a manufacturing strategy that aims to eliminate waste and maximize customer value. What are Lean tools and how do they work? Lean Management tools are techniques and methods that help organizations identify and eliminate waste in their processes.

In this article, we'll focus on some of the basic Lean tools that are most commonly used: 5S, TPM (Total Productive Maintenance), and Six Sigma. They play a key role in improving production and logistics processes. We will also look at how efectivo, using RTLS (Real-Time Location System) technology, enables the effective implementation of these tools, helping companies achieve higher efficiency and quality of operations.

5S in Stock With Efectivo System

One of the basic methods of Lean Manufacturing is the 5S method, which involves tidying up workstations, eliminating unnecessary items, standardizing processes, and maintaining cleanliness. This principle of workplace organization includes five steps, such as Sorting, Systematics, Cleaning, Standardization, and Self-Discipline, and the key element to the success of the implementation of the 5S method is monitoring and maintaining order.

Efectivo allows you to effectively monitor the movement of resources and identify areas for improvement, such as better organization of workstations. Thanks to efectivo, employees can effectively manage tasks, control material consumption and minimize losses.

How Does Efectivo Support 5S?

Sorting (Seiri)

Efectivo enables real-time tool location and makes it easy to remove unnecessary items from the job site. It allows for easier space management and increased work efficiency.

Example: In a logistics warehouse, an employee notices pallets blocking the way. Using the emergency button on the efectivo tagsignals the area from which the remaining pallets need to be removed. This triggers a problem report. The manager receives a notification and orders the pallets to be removed immediately to clear the way for the forklifts.

Cleaning (Seiso)

This principle applies to regular cleaning and maintenance of the workplace and tools to keep things tidy and improve safety. Efectivo monitors the frequency of cleaning work, reminding you to clean regularly and pinpointing areas that need attention.

Example: An employee performs maintenance on a machine, and efectivo monitors their location and working time on the machine. In the Distance between resources report available in the efectivo system, information about the maintenance performed appears.

Self-discipline (Shitsuke)

Efectivo helps shape good habits and follow the established 5S principles, which contributes to implementing the principle of continuous improvement.

Example: In one of the production plants, the efectivo system measures how often employees follow the 5S rules by verifying the level of completion of assigned tasks. Employees who regularly report problems and maintain order in the workplace are rewarded by their supervisor - they receive e-coins, which can then be exchanged for rewards in efectivo APP.

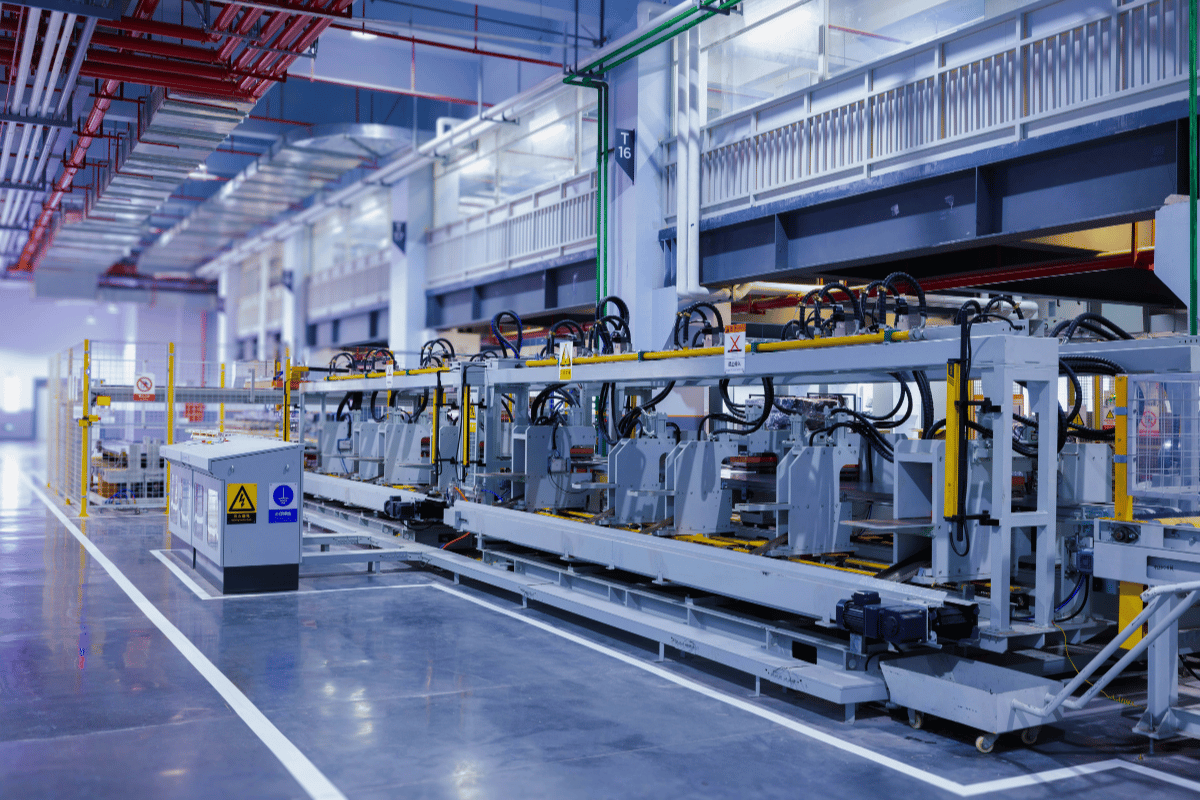

Total Productive Maintenance (TPM) - Full Performance With Efectivo

Total Productive Maintenance (TPM) is a strategy that focuses on preventing machine breakdowns and maximizing productivity. This tool is designed to ensure the reliability of the equipment and consequently minimize downtime. Efectivo allows you to monitor the condition of your machines on an ongoing basis, identify potential faults, and plan preventive maintenance. Thanks to efectivo, the management of the TPM process becomes more effective - it allows you to quickly respond to possible technical problems and allows you to optimize the maintenance cycle of your equipment.

How Does Efectivo Support TPM?

Regular inspection and maintenance of machines

Employees are responsible for basic maintenance and diagnostic operations, which reduces machine downtime and improves machine productivity. Efectivo allows you to monitor the location of assets in real-time, determining the time an employee is near the machine.

Example: A plant manager uses efectivo to assign a task to employees for maintenance activities, and employees are given a goal related to the maintenance of the machine. Inspections and maintenance can then be monitored and confirmed by reports prepared from the RTLS system. This makes it easier to verify whether the employee was in the designated place and at the specified time. Employees who have completed maintenance tasks on time can be rewarded with an incentive system by claiming e-coins on efectivo APP.

Employee engagement

The key principle in the TMP method is that all employees should be involved in the process to improve work. Efectivo allows employees to report failures.

Example: Each employee intervention is recorded in the system. In addition, employees who show initiative in detecting waste and improving processes can be rewarded as part of the efectivo incentive system - they earn e-coins in efectivo APP.

Ensuring safe and hygienic working conditions

The purpose of this rule is to protect the health of employees and prevent accidents. Efectivo allows you to increase the level of employee safety by monitoring the location, signaling threats and quickly providing assistance in emergency situations.

Example: Each employee has a tag (e.g. worn on a belt, clothing) with an emergency button. The system works in real time, locating employees on the premises of the plant. In an emergency situation (e.g. accident, fainting), the employee presses the emergency button on the tag. The shift supervisor receives information about the signaling of the hazard and the exact location of the employee, so that he can quickly provide assistance to the employee on the scene.

Regular training of employees

Training in maintenance and machine operation is an important part of the TPM method, increasing the skills and commitment of employees.

Example: Employees newly hired in a manufacturing company receive access to health and safety courses and machine maintenance instructions in efectivo APP, thanks to which they have easy and constant access to knowledge.

Six Sigma and DMAIC - Process Improvement With Efectivo

Six Sigma is the last Lean Management tool on our list, but of course not the last in the Lean tool resource. It is a method of process improvement that is based on minimizing variability and errors. The key tool of Six Sigma is the DMAIC (Define, Measure, Analyze, Improve, Control) cycle.

How Does Efectivo Support DMAIC?

Define

Efectivo makes it easy to identify problems related to the flow of people and materials in a production or warehouse space. In addition, it allows you to identify areas where there is the most congestion or downtime. The system allows you to define project requirements, design a new warehouse, design new production lines or a new process in the warehouse or in production based on real data on the movement and flow of people in the model space.

Example: In a furniture manufacturing plant, efectivo analyzes data on the time it takes for production workers to complete tasks. Frequent downtime has been detected due to the lack of components on the production line. The team defines it as a key problem to be solved and thanks to this, the process is streamlined.

Measurement

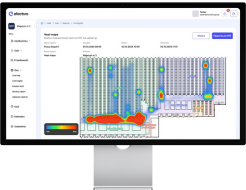

Efectivo allows you to collect and analyze data on your current processes to identify areas for improvement.

Example: On the assembly line, the RTLS system tracks the movements of workers and materials. With precise data from the RTLS efectivo system, the company identifies inefficient areas of production.

- Spaghetti diagram: Monitoring and documenting the actual flow of materials and workers makes it possible to identify inefficient routes.

- Heat map: Identifying high-traffic areas allows you to assess the use of space.

- Traveled Distance Report: Measuring the distance traveled by employees or equipment helps you identify wasted time and energy.

- Distance Report Between Two Assets: Analyzing the distance between critical assets can indicate potential delays in the process.

- Asset Speed Report: Tracking the speed of your assets helps you identify delays and speedups in the process.

Improvement

Efectivo allows you to optimize processes based on real data, made available in the form of 9 ready-made reports. In addition, the efectivo incentive system encourages employees to implement the desired changes in the process.

Example: Management uses the functionality of the e-coin bonus system to reward employees who adapt to the changes introduced and follow the new guidelines.

Control

Efectivo allows you to track the implemented improvements to ensure their sustainability and effectiveness.

Example: Regularly monitoring processes with RTLS efectivo to ensure the sustainability of implemented improvements. Generation of periodic reports (e.g. spaghetti diagram, heat map) for continuous monitoring and control of processes. Use data from generated reports to quickly identify and respond to new issues.

Review

Testing and verification of designed processes is an important stage in Lean Management.

Example: Efectivo allows you to analyze and evaluate new processes or spatial plans. Thanks to data from reports, such as heat maps and spaghetti diagrams, it allows you to monitor results in real-time and compare them with the assumed project goals.

See also:

Lean Logistics: How does RTLS improve the implementation of lean management in intralogistics?

Lean Manufacturing And Lean Management Tools In Industry: Strategies For Optimizing Manufacturing Processes

Summary

Lean Management is an investment that can bring many benefits to a company in the long run. Remember that the main principles of Lean Management do not come down to a set of tools, but it is also a Lean culture, i.e. a management philosophy.

Efectivo is a versatile tool that perfectly supports the use of Lean Manufacturing tools such as 5S, TPM, and Six Sigma at various stages of production and logistics processes. Its functionalities, based on RTLS technology, m.in, enable efficient space management, machine monitoring and process optimization.

In the next article, we will look at how efectivo supports Lean Management methods, such as: Kaizen, SMED, Standardized Work and TWI.