In the age of modern technology, precise location analysis is playing an increasingly important role in warehouse and production management. Real Time Location Systems (RTLS) allow tracking and monitoring the location of objects and employees in real time, significantly increasing the efficiency and safety of operations. In this article, we will discuss what RTLS is, what technologies are included in it, and how location analysis supports warehouses and manufacturing companies in achieving greater profits and optimizing processes.

What is RTLS and what are the main technologies?

Introduction to the topic and key concepts (RTLS, UWB, location analysis)

RTLS (Real Time Location System) is a technology that makes it possible to pinpoint the precise location of assets and people in a given location, most often in production halls, warehouses or logistics centers.

RTLS location analysis allows the display of real-time information about the location of objects, which is crucial for warehouses and manufacturing companies. One of the leading technologies used in RTLS systems is UWB (Ultra-Wideband), which provides high accuracy asset tracking even in harsh industrial environments.

UWB technology is distinguished by its high location accuracy and greater range compared to other solutions such as RFID (Radio Frequency Identification), Bluetooth or Wi-Fi, making it ideal for companies needing exact data in location analysis. RTLS is therefore not only a technology but also a set of tools that, based on location analysis, support businesses in optimizing processes.

How does RTLS work?

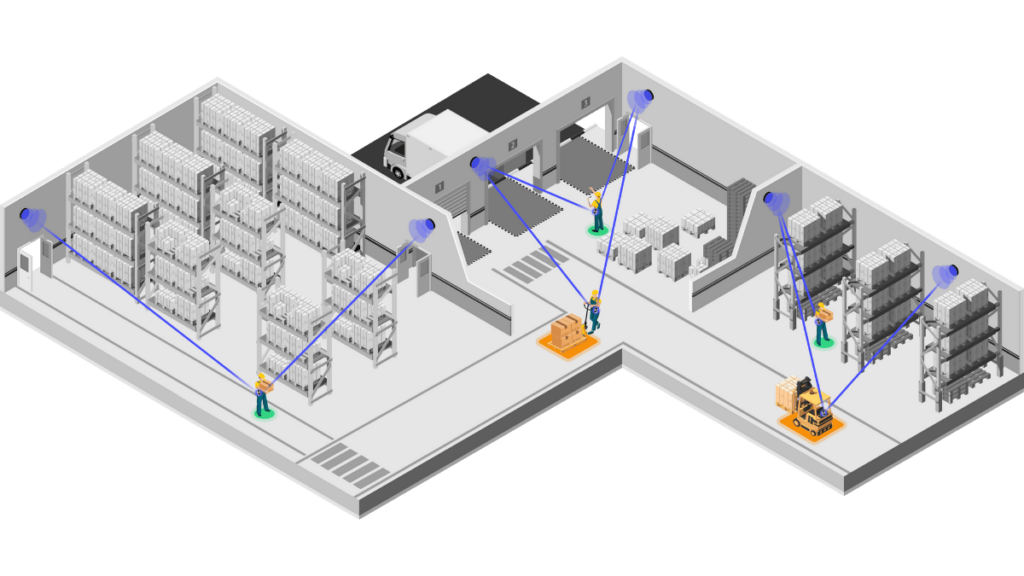

An RTLS system consists of receivers and transmitters that together enable real-time location of assets, personnel or equipment. With UWB technology, the system uses pulsed radio waves to measure the distance between the transmitter and receiver with a high degree of accuracy, allowing the location of objects to be monitored to within 30 centimeters. The operation of RTLS relies on measuring the time it takes for a signal to be transmitted between the receiver and transmitter, allowing precise position determination.

RTLS technology is used in logistics and manufacturing to track assets, locate employees and monitor the status of assets in real time. Compared to technologies such as RFID or Bluetooth, UWB features greater accuracy and the ability to track location over a greater distance. RTLS works by transmitting data to a central database, where it is processed and analyzed to display real-time information on the location of objects.

RTLS systems in warehouse management

The importance of location in warehouse management

In modern warehouse management, precise location of assets, goods and employees plays a key role. The use of RTLS (Real Time Location System) systems enables accurate real-time tracking for better workflow and increased efficiency. With RTLS, warehouse operators can monitor every aspect of operations, resulting in optimized processes and improved safety.

Location analysis and process automation

RTLS systems enable the automation of many warehouse processes by analyzing the location of objects in real time. With accurate data on the location of goods and equipment, it is possible to create efficient work schedules and organize traffic in such a way as to minimize the time required for individual operations. Automation based on location analysis contributes to increased efficiency and reduced human error, which is particularly important for large logistics operators handling high volumes.

Optimization of warehouse forklift routes

One of the most effective applications of RTLS is the optimization of warehouse forklift routes. Through real-time position tracking, RTLS can identify the most efficient paths to designated destinations, reducing unnecessary distances traveled and increasing productivity. By analyzing distance traveled, time and speed data, the operation of forklifts can also be adjusted to minimize travel time and avoid collisions, increasing safety in the warehouse.

Monitoring of resources in the warehouse

RTLS allows accurate monitoring of resources in the warehouse, both those for shipment and materials needed for daily operations. With real-time location analysis, managers can instantly locate any resource or storage location, greatly facilitating full pallet management and allocation. By monitoring resources, they can react quickly to changes in the flow of goods and optimize work, leading to increased warehouse efficiency.

Useful reports in warehouse location analysis: live map, heat map, distance traveled report, asset speed report, asset distance report, zone load report

RTLS efectivo offers a number of useful reporting tools to support warehouse management and enable analysis of operations on a daily basis. Database processing based on the information collected from the receivers makes it possible to create reports:

- Live map allows you to track the location of objects in real time in an extremely precise manner, which is invaluable for managing dynamic warehouse operations.

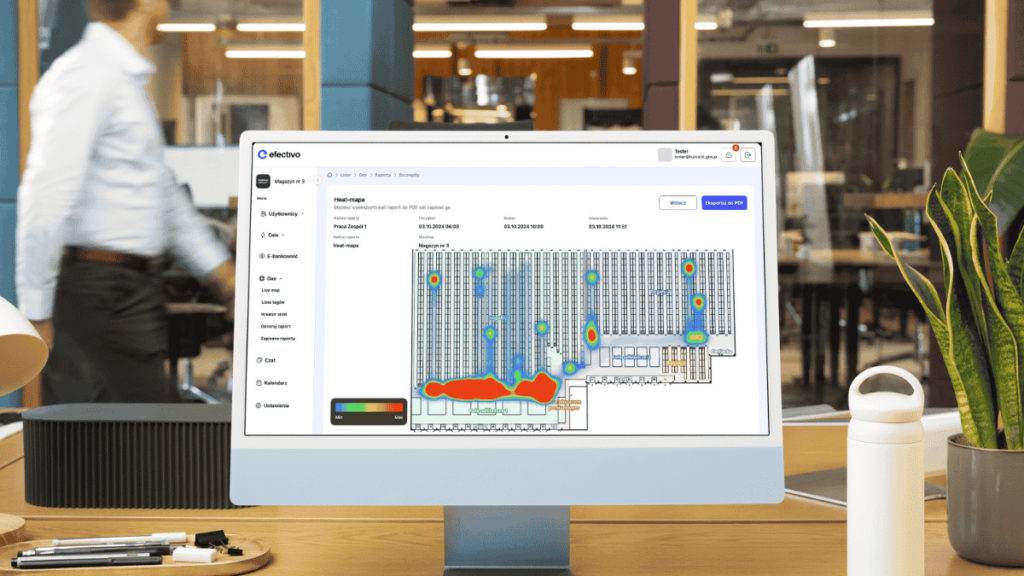

- Heat map, on the other hand, shows the intensity of traffic in different areas of the warehouse, indicating the busiest zones, which facilitates internal logistics planning.

- Other reports, such as the distance traveled report, the stock speed report and the stock distance report, provide detailed data on the efficiency of forklifts and employees.

- With the zone load report, you can easily identify areas of the warehouse that need more attention and adjust operational activities to better manage resources and space.

RTLS in industry

Locating the location of facilities, tools and workers

In industry, locating assets such as semi-finished products, parts, tools and workers is critical to ensuring the smoothness of the manufacturing process. RTLS allows these assets to be tracked with extreme accuracy, allowing the location of needed parts or machines to be located immediately and eliminating downtime resulting from searching for them.

With this system, production managers can better manage resources and monitor the location of workers on the production floor, helping to improve safety and operational efficiency.

Optimization of the production process

The use of RTLS allows optimization of the production process, enabling better time management and synchronization of the various stages of production. Analysis of the location of resources and employees allows the identification of potential delays and bottlenecks, which can be effectively solved by reallocating resources or rearranging processes. RTLS also provides automatic notification when more parts need to be delivered to the production line, helping to prevent downtime.

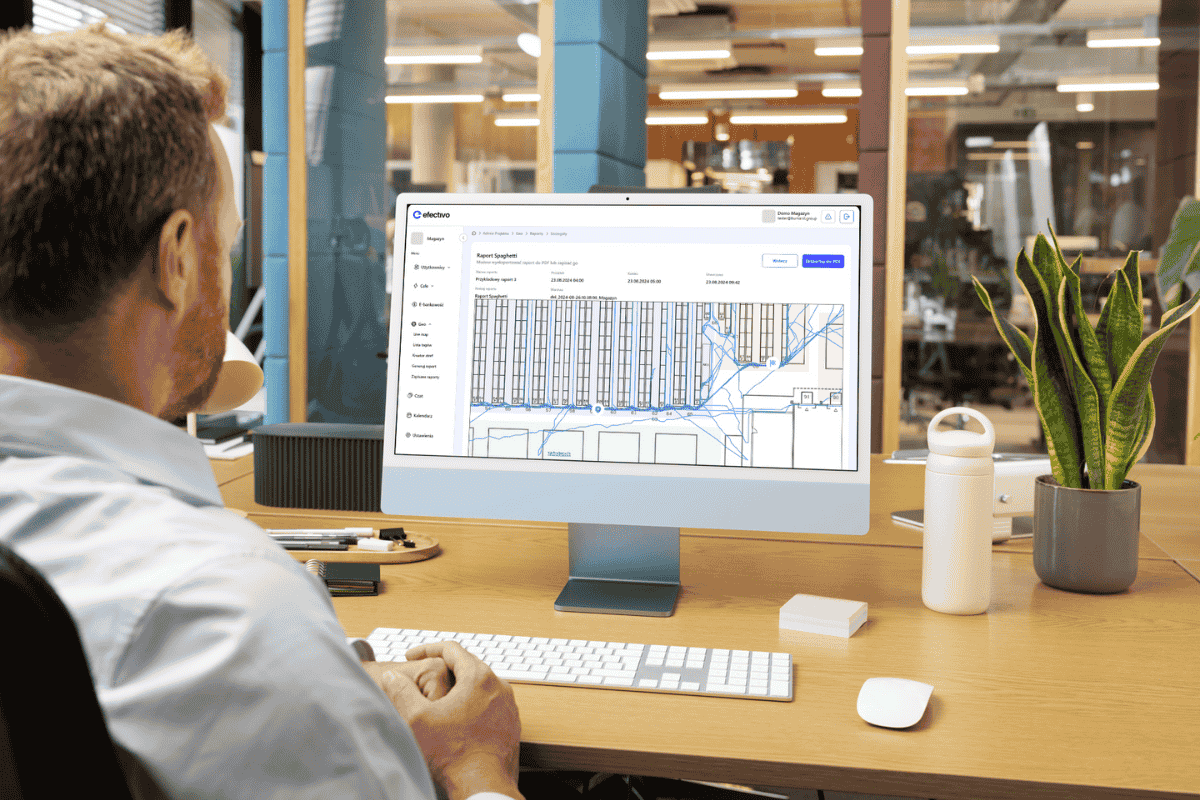

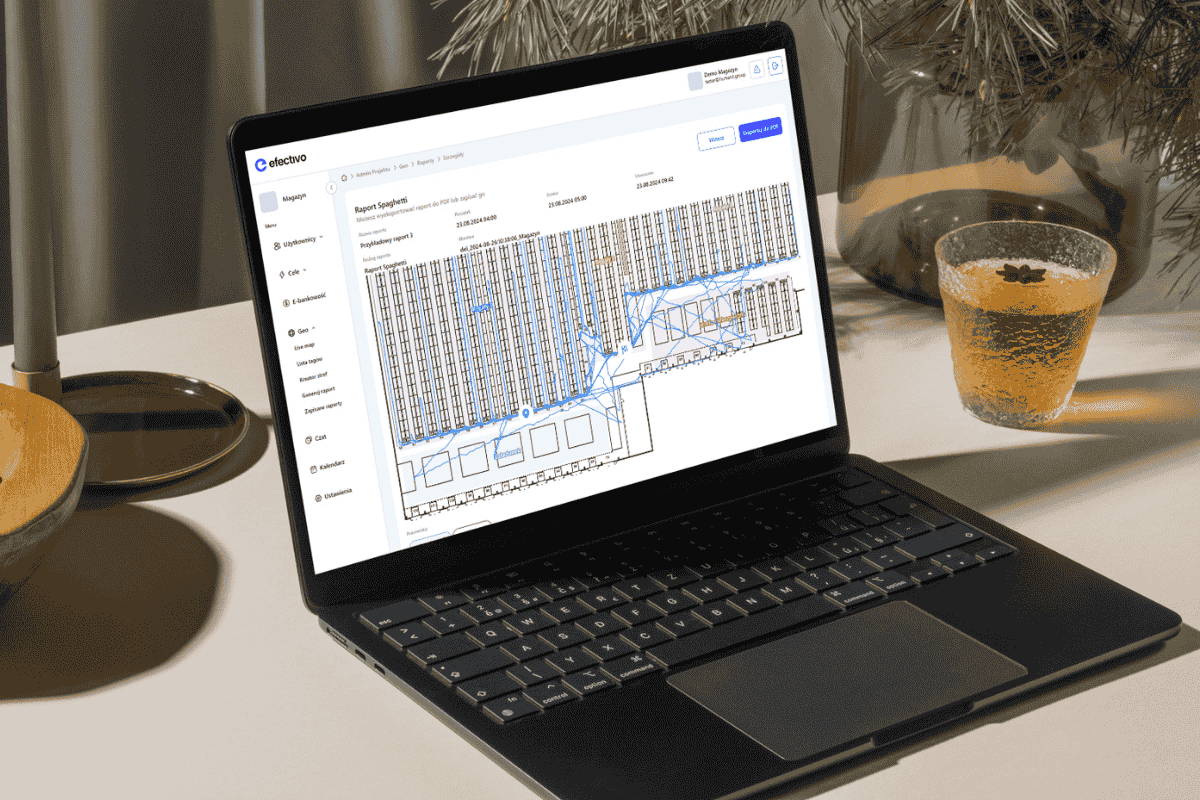

Location analysis and reports: spaghetti chart, heat map, zone load, resource distance, staying in hazardous areas

RTLS offers advanced analytical tools that provide valuable data on the location and movement of resources and employees. Among the most commonly used reports are:

- Spaghetti graph - shows the movement paths of employees or resources, allowing identification of unnecessary movements and areas for optimization.

- Heat map - shows the intensity of movement in different zones of the production floor, indicating areas with a high density of resources or employees.

- Zone load - shows how often and intensively each production area is used, which helps in effective space planning.

- Traveled Distance Report - measures the distances traveled by resources or employees, which is useful in analyzing the efficiency of moving around the plant.

- Staying in hazardous areas - monitors how much time employees spend in areas considered risky, which allows you to implement additional precautions and improve workplace safety.

With the reports provided by RTLS efectivo, companies can manage production and resources much better by analyzing key factors affecting production efficiency and operational safety in real time.

Would you like to learn more about the features of the system? Visit the subpage efectivo GEO.

RTLS benefits in intralogistics – solutions for large logistics operators

RTLS systems offer a number of benefits for intralogistics, optimizing logistics processes and improving space management. With RTLS technology, businesses can monitor resources extremely precisely, resulting in higher profits and operational efficiency.

RTLS receivers enable real-time tracking of resource locations, which supports monitoring of key factors such as space utilization, resource availability and zone load. RTLS also allows data to be automatically collected in a central database to support better-tailored operational decisions.

The future of location analysis

Developments in RTLS technology indicate the growing importance of this technology as the future of intralogistics. Increasing range, accuracy and the use of modern receivers are opening up new opportunities in large-scale asset monitoring. As location analysis becomes more precise, companies will be able to count on greater profits through improved operations management and security. RTLS remains a key tool to support the development of the logistics of the future and the efficient management of workplaces.