Modern warehouses and production halls require efficient organization and constant control over the flow of people and resources. The key to effective management is access to up-to-date data, in real time and with the highest precision. With Live Map in the efectivo system, you get a 24/7 visualization of movement in the warehouse, which allows you to immediately respond to irregularities, optimize processes, and increase work safety.

In this article, we will show you how Live Map works, its benefits, and how to use it in everyday warehouse or production hall management. We will also discuss the Zone Builder function along with the Zone Percentage report

What is a Live Map in the efectivo system?

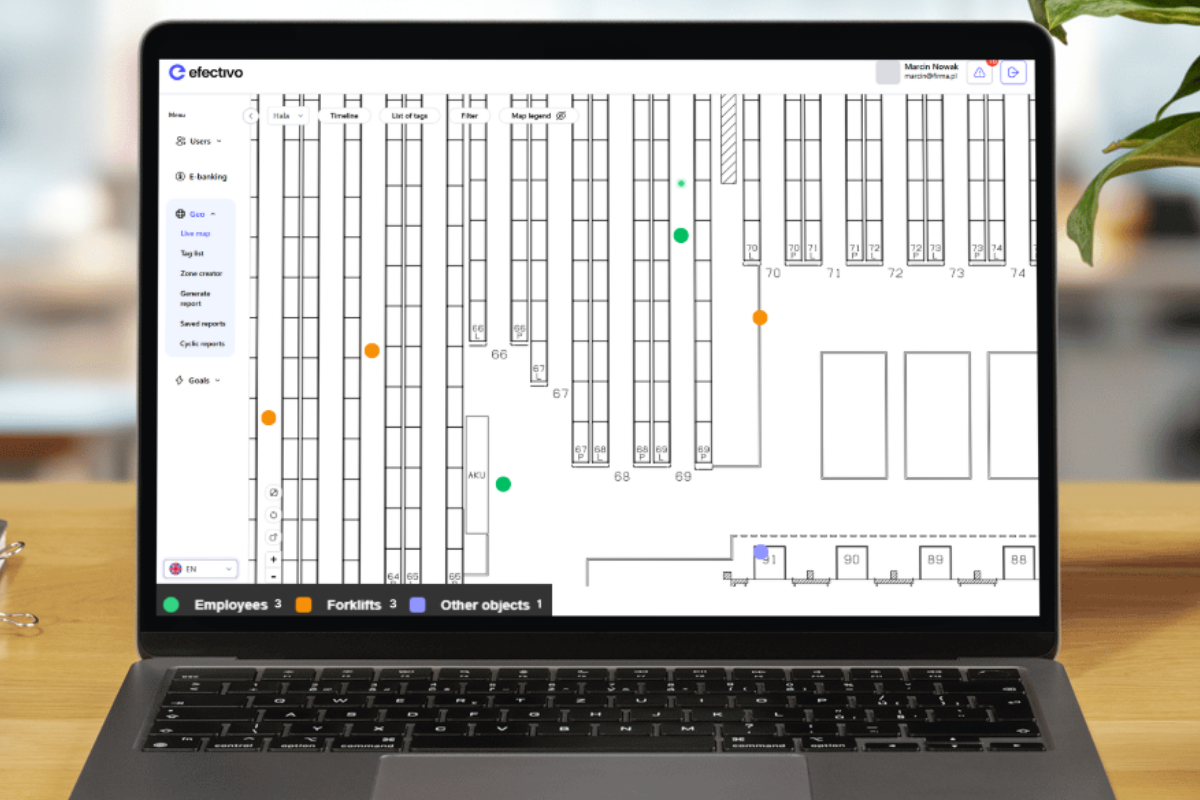

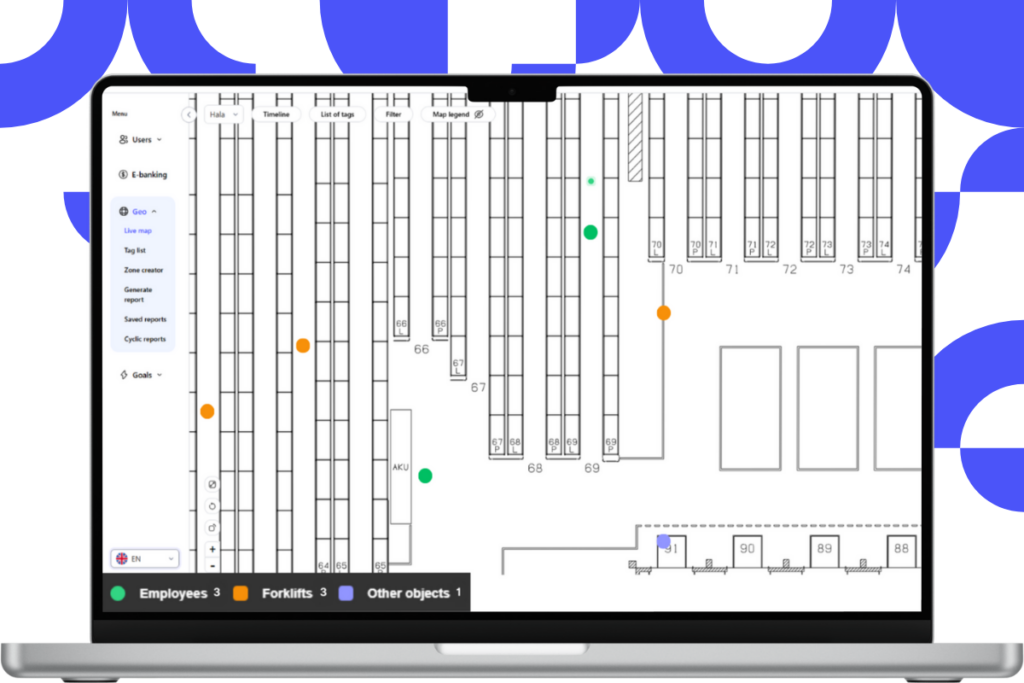

Live Map is an advanced tool for visualizing the monitored space, which shows the current location of employees, forklifts, and machines in a given area in real time. Thanks to Live Map, the warehouse or shop floor manager has full control over the flow of resources and receives information:

- where exactly the employees are, with an accuracy of 30 cm.

- how forklifts and machines move – with position updates every 1 second.

- whether assets are moving along optimal routes – identifying redundant movements and bottlenecks.

It is an invaluable source of knowledge and the basis for optimization, such as reducing warehouse costs or better organization of work.

How does the real-time location system work?

Let's remind you what real-time resource localization with efectivo is all about. Well, RTLS (Real-Time Location System) technology based on Ultra WideBand (UWB) is used to monitor a given area. The system includes, e.g., anchors (receivers) and tags (transmitters). The system measures the time it takes for a radio wave to travel from tag to anchor, which allows for accurate determination of the distance and position between them in 3 directions. This data is sent to the server and then displayed on the Live Map, allowing precise tracking of location and movement.

The efectivo system of precise location of resources inside rooms is characterized by:

- location accuracy up to 30 cm,

- refreshing data every 1 second,

- the ability to view Live Maps from anywhere (online),

- 24/7 operation regardless of lighting conditions or obstacles, unlike cameras.

What data does Live Map present? Functionality overview

Live Map in the efectivo system is a real command center, presenting a rich set of data in a clear form. Let's take a detailed look at what information you can observe on the screen:

- View of a warehouse or production hall with full infrastructure - Live Map will display the entire space, i.e.:

- layout of racks with the possibility of identifying specific aisles (e.g., A-01 to A-20)

- functional zones - goods receipt (e.g., "Dock 1-3" zone), shipping zones or dangerous zones, excluded from traffic.

- logistics points - loading ramps, packing stations, quality control points or trolley parking areas

- safety infrastructure - escape routes, fire extinguishers and first aid and assembly areas

- Tags in motion - the system visualizes in real time the movement of tags worn by employees or attached to forklifts and machines. In addition, each tag can be assigned to a specific asset, so you can locate a specific employee or vehicle. By monitoring asset activity, you can identify downtime and optimize task allocation. Live Map also allows you to locate delays and possible problems in the process, allowing you to eliminate them effectively. By tracking the movement of forklifts and other vehicles, you can better control their use and avoid collisions that lead to damage to goods and equipment.

- Zone view - imagine that in a warehouse, for example, you mark zones with hazardous substances in red, and the system automatically registers any unauthorized presence in these areas. In eFecivo, you can mark zones with colors, for example, red to mark danger zones. This will help you avoid unwanted accidents.

- Up-to-date alarms and notifications – The Live Map displays up-to-date alerts, e.g., when an employee calls a supervisor to the place where an accident occurred, appears in a traffic-free area, or reports damage to goods.

Benefits of Live Maps

Live Map is not just a monitoring tool, but a real-time decision support system that provides specific, actionable information. This is the key to effective warehouse management. Here are the most important benefits of using this tool:

- Immediate control over the flow of resources – thanks to the preview of the hall, you will see what is happening in the warehouse in real time with an accuracy of 30 cm, where employees and machines are at the moment, without having to walk around the hall. You will react to congestion and bottlenecks, for example, if the forklift has been sitting in one place for too long.

- Process optimization – having full visibility into the operation of the warehouse, you will reduce empty runs, identify unnecessary movements, and improve operations. You will optimally plan the layout of the warehouse and better distribute goods in a situation where employees often move between its two extreme points.

- Increase work safety – by monitoring risk zones, you will prevent accidents. Alerts displayed on the Live Map will help you with this if an employee appears in a danger zone (e.g., near machines). In addition, controlling the movement of forklifts will help avoid collisions.

- Verification of compliance with procedures and accepted standards – you will find out whether employees perform tasks according to the schedule and whether forklifts move along designated routes.

Examples of how Live Maps can be used for optimization

In one of the warehouses, Live Mapa revealed that forklifts create congestion at loading ramps. Thanks to the introduction of a loading schedule and a change in traffic organization, it was possible to reduce the parking time by 35%.

In the factory where heavy machinery operates, dangerous areas have been designated. When an employee entered such a zone without the required permission, the system sent an alert to the manager visible on the Live Map. This significantly reduced the number of incidents.

In another company, Live Maps analysis showed that employees moved too often between distant racks. After changing the warehouse layout and better distributing goods, picking times were reduced by 25%.

The role of the "Zone Creator" in warehouse space management

Zone Builder is a tool that allows you to customize space monitoring to your needs. You can define, categorize, assign a meaning and analyze the movement of assets within them. This will help you make the best use of the potential offered by the efectivo system.

Zone Creator features

- Map zones from picking and loading to hazardous or traffic-free areas.

- Categorize zones – by color-coding and attributes (e.g., "high priority," "limited access").

- Defining danger zones and setting automatic alerts – the system can send notifications when an employee stays in a given area for too long or stays in a zone marked as dangerous, excluded from traffic.

- Generating reports – by defining zones, you can analyze, among other things, how much time resources spend in each zone. You will use a report called "Percentage share in zones".

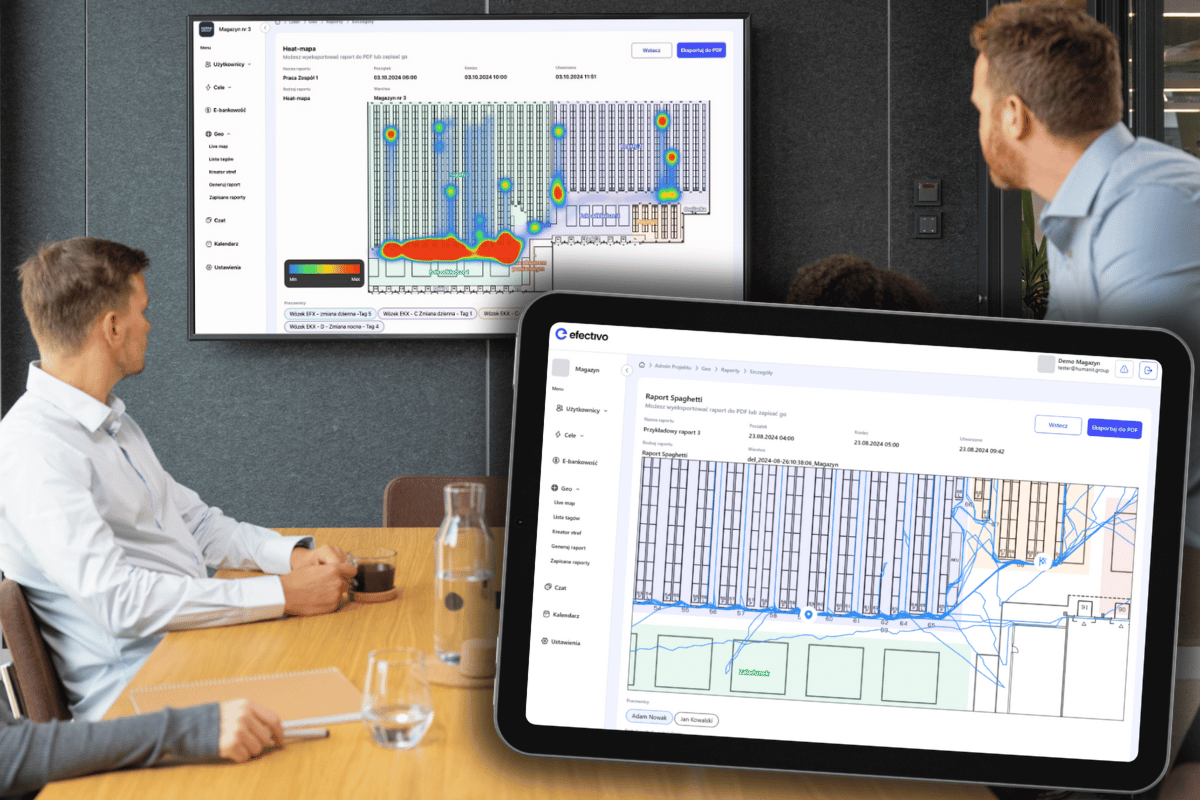

Report: "Percentage of Zones" - Find out where time is being wasted

The RTLS system not only shows the current situation in the warehouse or production hall, but also collects historical data that can be used to generate many reports, including "Percentage share in zones". This report shows how working time is distributed among different areas of the warehouse, and the results are expressed as a percentage – e.g., "Picking zone – 45%, Loading zone – 30%". You can filter the data according to the criteria that are convenient for you. Thanks to the analysis of the report:

- Identify bottlenecks – if employees spend 50% of their time in the loading area, it may indicate that you need to increase the number of workstations.

- You will optimize the routes of forklifts – if the forklift stays in the parking zone for too long, it is worth analyzing the causes.

- You will assess the effectiveness of the implemented changes – a comparison of whether the introduced improvements have actually reduced the time spent in problem zones.

Summary:

Live Map in the efectivo system is a revolution in warehouse and shop floor management. Thanks to precise real-time location (with an accuracy of 30 cm and data refreshing every 1 second), you gain immediate insight into the flow of resources – you know where employees, forklifts, and machines are, without having to walk around the hall. By monitoring risk zones, you will improve safety and avoid costly vehicle collisions.

If you want to increase the efficiency of your warehouse, reduce costs, and improve safety, Live Map is the perfect solution.

Contact us and see how it works in practice!

Read also Efficiency On A Plate – How Will The Spaghetti Diagram In Efectivo Improve Your Warehouse?